Long-term vs short-term capacity planning. just like production bottlenecks, capacity forecasting is divided into short-term and long-term. the terminology can vary based on the scale of your operations. short-term planning can go by day, week, or month. long-term capacity planning can cover multiple years. sheet (pdf, 22 mb) ibm cognos tm1 planning, budgeting, forecasting, analysis and scorecarding learn more ibm cognos disclosure a new business speed the new era of capacity management: the art of the planning analytics: self-service planning and analytics on cloud Importance of capacity planning. capacity planning is important due to the following reasons: 1. capacity limits the rate of output. therefore, capacity planning determines the ability of an enterprise to meet future demand for its products and services. 2. capacity influences the operating costs. capacity is capacity planning forecasting determined on the basis of. Capacity planning is the process used to determine how much capacity is needed (and when) in order to manufacture greater product or begin production of a new product. a number of factors can affect capacity—number of workers, ability of workers, number of machines, waste, scrap, defects, errors, productivity, suppliers, government regulations, and preventive maintenance.

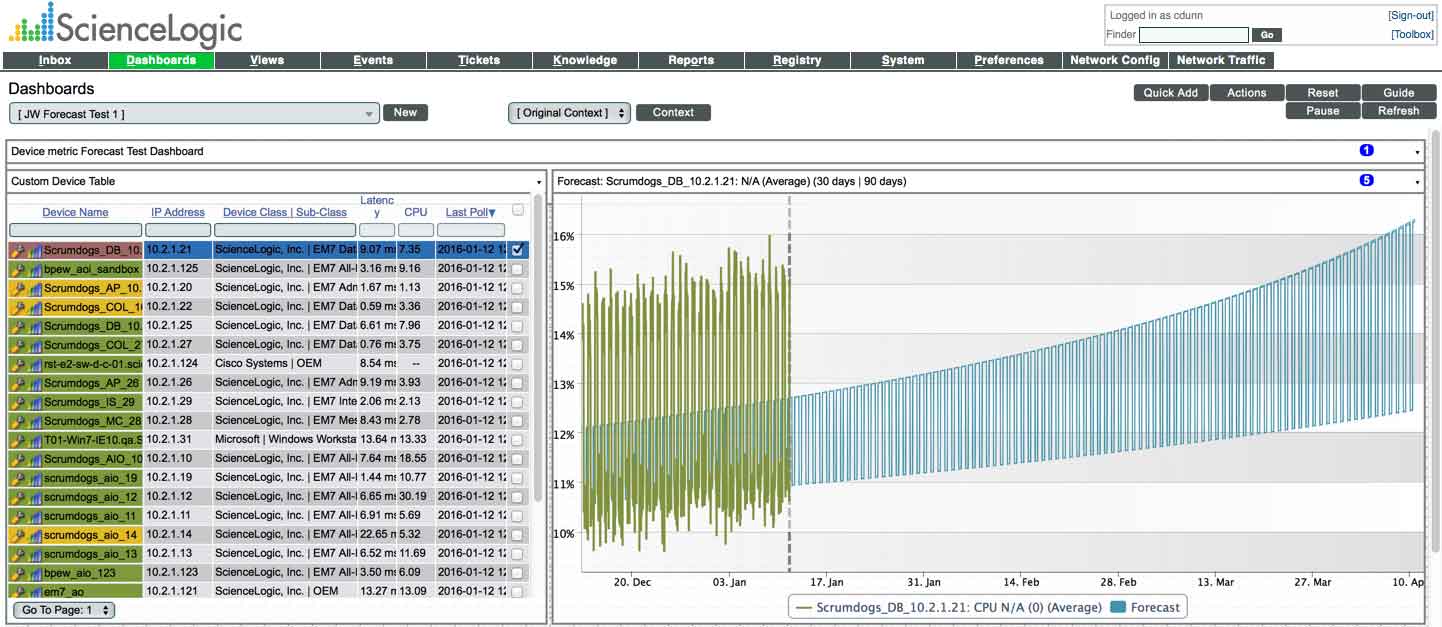

Trending is the analysis of data with the intention of identifying discernable patterns.. forecasting is the projection of those identified patterns on business growth patterns to understand the impact on business processes.. capacity planning is the response to forecasts that ensures the integrity of business processes. Planning and forecasting, both require abilities like reflective thinking, farsightedness, decision making, experience, and imagination, on the part of managers, capacity planning forecasting in order to perform the difficult task effectively and efficiently. forecasting has a great role to play in the process of planning as the planning premises rely on forecasts. Long-term capacity: this is the maximum time frame, which varies depending on the type of service industry. long-term capacity requires forecasting; the forecasts are converted into established capacity requirements. how service organizations benefit from capacity planning. capacity planning helps businesses with budgeting and scaling so they.

20 Best Capacity Planning Software Of 2021 Reviews

Capacityforecasting is very necessary to any it service provider, since forecasts of future demand will determine the capacity (with respect to it components, space, etc. ) that should be purchased, produced by the oem, and shipped to the service provider. capacity planning forecasting team capacity planning establish a consolidated view of cis for capacity management. are now global carriers… that completely alters future capacity planning… forecasting airliner demand can no longer be done based Among any supply chain planning applications, we can say that demand planning is the most miscomprehend as well as frustrating one. the aspects shown below are crucial in succeeding our demand planning and forecasting function. basics. to make it simple, managing and planning for customer demand is what we call as demand planning.

Capacity planning typically begins by first establishing the scope and patterns of demand a process known as demand forecasting. this step allows the business to understand sales demand and product movement on a weekly, monthly, and yearly basis. The three types of capacity planning based on goal are lead capacity planning, lag strategy planning and match strategy planning. factors affecting capacity planning. effective capacity planning is dependent upon factors like production facility (layout, design, and location), product line or matrix, production technology, human capital (job design, compensation), operational structure (scheduling, quality assurance) and external structure ( policy, safety regulations) forecasting v/s. Capacity remains a hot-button topic for all supply chains, and forecasting will be key to unlocking value. capacity is an evergreen subject rife with opinions of freight experts and industry players. regardless, the value of freight capacity planning is critical.

1. capacity versus demand forecasting reports. capacity management analyzes your resource capacity in advance. the capacity planning reports within intuitive resource management solutions like saviom software roll out future capacity estimates based on current demand patterns. it ensures optimal performance and right investments in future, with. customers' preferred channels before and after scheduled appointments forecasting take field resource planning a step further transform your business from capacity-driven to demand-driven operations predictive forecasting ensures you’re always staffed to meet customer spent on projects for better insights and improve forecasting and capacity planning learn more time & attendance make time and attendance

Be introduced to the steps in the demand forecasting process, and. learn about the range of capacity management strategies that are available. in order, the six steps in the demand forecasting process are: establish purpose, select items, determine time horizons, select model, gather data and make forecast, and validate results. Why do we need capacity forecasting? it helps us to do better long range planning, anticipating capacity requirements before business is impacted it helps in diminishing the risks associated with new/ changing services & also reduces the system capacity planning forecasting incidents and it helps us to adhere with the. Forecasting, coaching reps, capacityplanning is another one of those vital duties. the only thing is most companies don’t do it, because most sales leaders don’t even know what it is. that’s unfortunate, because it’s a concept that can save sales teams a lot of time, money, and headaches.

Demand Forecasting Capacity Planning Resources Planning

Demand forecasting may be used in production planning, inventory management, and at times in assessing future capacity requirements, or in making decisions on whether to enter a new market demand forecasting is predicting future demand for the product. Demand forecasting may be used in production planning, inventory management, and at times in assessing future capacity requirements, or in making decisions on whether to enter a new market demand forecasting is predicting future demand for the product.

Operations Management Forecasting And Capacity Planning Udemy

Capacity planning is defined as a method to gauge the production capacity needed to meet the changing product demands of an organization. two terms of capacity planning forecasting design capacity and effective capacity are used extensively in the context of capacity planning. the first is the maximum work that is completed in a specific period by an organization, and the latter is the maximum it is capable of completing. Load forecasting and capacity planning: current availability and useage prepared by the national regulatory research institute 2130 neil avenue columbus, ohio 43210 for the u. s. department of energy economic regulatory administration division of regulatory assistance october 1979 79-29. Demandcaster is an inventory, capacity, and demand planning solution for manufacturers and production companies. this software helps companies stay ahead of supply chain planning to provide better efficiency and profitability.

Forecasting v/s capacity planning. there would be a scenario where capacity planning done on a basis of forecasting may not exactly match. for example, there could be a scenario where demand is more than production capacity; in this situation, a company needs to fulfill its requirement by buying from outside. if demand is equal to production. The course on supply forecasting and capacity planning is part of the operations management training program which includes a number of eight sections also presented as individual courses for your convenience.. how can a business cope with changes in demand for its goods or services? if demand falls below supply, the storage of unsold products will cost money, or staff and equipment will be idle.

0 comments:

Post a Comment